Last year I got a letter from a wooden spoon collector named Norman D. Stevens of Storrs, Connecticut. It seems that he became interested in collecting spoons by American woodcarvers. One of his internet searches pulled up my name and he sent a letter inviting me to contribute to his growing collection which I did.

The more I thought about this, the more I appreciated what Norman is doing. He is documenting the state of wooden spoon making throughout the world in the early 21st century. Norman has complied a directory of perhaps as many spoon makers he has identified, and is maintaining hard copy files with background information and correspondence with many of those artisans.

More importantly, he is creating a catalog describing each contributor to his collection and his or her spoon. A number of his spoons are on display through May 23, 2010 in an exhibit at the American Association of Woodturners in Saint Paul, MN.

Norman Stevens Spoon Collection Display

There will also be a special display of many of his spoons, with presentations by Norman, at the AAW Symposium in Hartford, CT from June 19-20, 2010. That exhibit is open to the public without charge. Further information can be found at: http://www.woodturner.org/sym/sym2010/. AAW will be issuing and selling a catalog for the exhibit at the Symposium that will contain color images of about 100 of the spoons. There is also an exhibit scheduled for the Gallery-on-the-Plaza of the Homer Babbidge Library of the University of Connecticut. If you are interested in his project his e-mail is: normanstevens@mac.com.

What a nice thing to do! Spoon makers are not exactly in the spotlight of American woodworking so to pay tribute to the many fine craftsmen who devote their energies to spoon making is like a breath of fresh air to me.

Spoons Got Me Started in Woodworking

It turns out that wooden spoons were my first venture into woodworking as an adult. I had cut down a maple in my back yard to make some light for a vegetable and rose garden. The wood was so pretty and white that I couldn’t bear to split it all for firewood so I saved a log or two.

By the time I got around to a project with the maple it had spalted nicely. My first impression was that the wood was ruined but the more I worked with it the more I came to appreciate the spalting. As I learned more, I realized that I had cut a curly maple log that had spalted and then I wished that I had saved the whole tree.

There are as many ways to make a wooden spoon as there are wooden spoon makers. I thought I would just share some of my thoughts about the craft. A test I once took indicated that I was a pragmatic idealist. That sounds like a bit of an oxymoron but it really does describe two opposite aspects of my character.

Spoons For Looking And Spoons For Cooking

I do appreciate the intricate work of spoons with all of the delicate cut out work, but the spoons I wanted to make were to be used in cooking. Every fine cook knows that nothing beats a good wooden spoon. So my spoons had to be practical and built to last.

My first ones were a bit clunky but seemed to please the intended users. On the other hand, I wanted my spoons to reflect the beauty of nature stored in the wood and that this be set off by some refinement of the design.

One thing I looked for in the design was a sturdy handle. The flimsy ones from the box stores are too easy to break. I wanted ones that would hold up to the hardest tasks. I got an e-mail from one of my customers this year. She said the spoon I made for her was the only one that was up to stirring her fruit cake batter and it was her favorite spoon. That appealed to the pragmatism in my nature.

Taking Advantage of Wood Grain

As I learned more about woodworking I realized that making the handle parallel to the direction of the grain made for a handle which was stronger and not quite as much mass was needed to keep the handle sturdy.

With more experience I learned that the grain does not always run straight in every piece of wood and that it was alright to have the handle curve this way or that following the grain of that particular log. In the colonial days the wood for spoons was rived with a froe (a metal blade which was pounded into the end grain). This caused the wood to split right along the path of the grain and all handles produced in this manner had handles which followed the grain.

Some still rive the wood for spoons and this is a fine way to make them. Yet I need to do production work as I sell many spoons at craft shows. They are one of the most consistent sellers. I have probably made more than a thousand spoons and so now I cut my blanks from wood which has been sawn into planks with the band saw. The band saw is such a useful tool as it allows you to make planks out of any log or branch that comes your way.

Below is a picture of a few of my spoon blanks.

Another thing I learned is that cooks like spoons that are not completely symmetrical and they like odd shapes. It may help them locate their favorite from their collection and the odd shape or curved handle may be just what is needed for a particular job.

So now I vary my design to suit the wood grain and my whim and just draw the design freehand on the plank. This way it is easy to follow the grain in the handle. I then go back to the band saw and cut the outline drawn on the plank.

Gouging the Spoon’s Bowl

The next challenge is to hollow out the bowl of the spoon. Again, the ways to accomplish this task are numerous. I settled on using a spoon gouge with a curvature that suits the maker. Too shallow and the edges of the gouge will dig into the sides of the spoon bowl… Too steep and you will get deep grooves in the wood and not a smooth flowing curve of the spoon bowl.

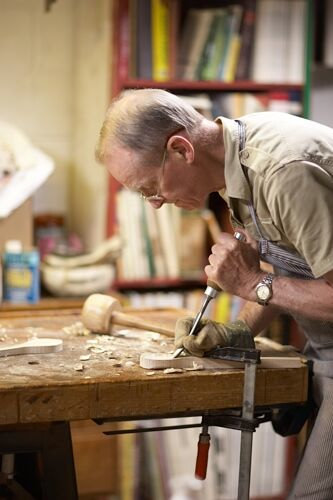

The width of the gouge is also a matter of personal choice but I use one wide enough to remove plenty of waste wood with a single pass. I have had a number of bent gouges but they seem to have a propensity to wander off when I do demonstrations and the only one left is one that never leaves my shop. It is a firmer gouge, meaning that it is thicker and will stand up to repeated heavy use. It is the one in use in the picture below.

Now unless you are a whole lot stronger than I, you will not be able to push this gouge through the wood for very long using just the muscles of your hands and arms. This is especially true of hard woods such as fruit woods like cherry and apple.

To remove large amounts of wood quickly I use a wood carver’s mallet. The one shown above I made of a dogwood head (very hard) and a hickory handle. Beech also works well.

Notice that the handle of the gouge has a metal ferrule on the end which keeps the wood of the gouge handle from splintering from repeated blows. With these tools I am able to remove large amounts of waste wood quickly. I keep the spoon blank secured to the work bench with a simple clamp.

I start at one end of the bowl and remove some wood. However, if I go too deeply the wood will tend to split and ruin the blank. So I go as far as I dare and then remove stock from the opposite side. I always work in the direction of the grain. By going back and forth from one end to the other I can remove large amounts of waste in a short period of time.

By angling the cutting edge of the gouge one way or the other you can begin to shape the walls of the spoon bowl. The straight cuts work best for roughing out and for the bottom of the spoon. Below I am cocking the gouge to one side to make the near wall of the spoon bowl.

Here you need to exercise care not to take such big cuts as will cause splitting because you are now working on a thin rim of the spoon with less margin for error. You will find that some species of wood will split far more easily than others.

You can only get so much control of the cutting edge of the gouge when you are pounding on it with a heavy carver’s mallet. So for finer cuts I just use muscle power without the mallet striking the gouge as seen in the picture below. Notice I use a glove on the hand that guides the cutting edge.

Considerable force is needed to make even these lighter cuts and if the hand slips it may hit sharp corners of the band sawn edge of the blank and cause cuts. Using a glove in the hand that does not grip the gouge handle cuts down on the need for band aids and loud exclamations.

For the finest cuts I remove the blank from the clamp on the bench, sit comfortably and use the gouge free-hand as you see me doing below. This gives maximum control and allows clean up of any rough areas left from previous steps.

In my earlier spoon making days I used to carve the outside of the bowl of the spoon and the handle all by hand. I used a combination of gouges, draw knives and small pattern maker spoke shaves to remove the waste. However this is a slow process.

Now I use a large belt sander with an aggressive planer belt from Klingspor. With a bit of practice you can smooth the contours and remove all the bandsaw blade saw marks. You can even round out the handle.

Sanding and Oiling the Spoons

What remains is to hand sand the spoon. I do not go above 220 grit as these spoons are for cooking and finer finishes are not important. I oil my spoons with sesame oil. I used to use mineral oil but since this is a petroleum based product and not renewable, I feel more comfortable using a vegetable oil.

I choose sesame oil as it has the longest shelf life of all the non-drying oils and does not become rancid easily. This is due to unique antioxidants found in sesame oil and not in other vegetable oils.

I don’t recommend olive oil as it spoils very quickly and you get a tacky residue building up on the utensil. A food safe drying oil such as tung oil can also be used.

Care of the finished product is very easy. Just wash in soapy water and let it air dry. Over the course of time the surface may become whitened due to fragmentation of the fibers with repeated use and washings. Just apply another coat of sesame oil and the finish is restored.

For heavily used spoons a light sanding before reapplication of the oil is all that is needed. A well cared for spoon can last for generations. Below is a picture of spoons ready for oiling.

Other Methods of Wooden Spoonmaking

I would just like to say a few words about other methods of making spoons. If you only want to make one or a few, then you may enjoy carving them completely by hand. This allows for great individual expression.

There are even special tools for hollowing out the bowl such as curved bladed carving knives or special spoke shave like tools with a curved blade. Just bear in mind that the curve of the spoke shave tool will limit the radius of the bowl of the spoon.

More recently I have used special carbide cutting burrs with a flexible shaft tool. There are burrs which are suited to hollowing the bowl of the spoon. There is a bit of a learning curve to this. It requires a firm hand and practice to know how aggressively to make the cuts or you will find that the bit wanders and wipes out the rim of the spoon you are trying to make.

It is easier with one of these tools to make a deeper bowl in a spoon than you can with spoon bent gouges. After using the burrs I clean up the tool marks with the hand held spoon bent gouge using light finishing cuts. So for certain shapes I have actually come to prefer this method of hollowing.

Some spoon makers turn a blank on the lathe. This gives a very symmetrical round handle and outside of the bowl of the spoon. Then they may use a saw to remove waste from the spoon bowl and use some hollowing process to carve the inside of the spoon bowl.

Some even mount this on the lathe and turn it out. Be advised that what you have is a spinning propeller and take care to keep fingers away from the spinning handle which you cannot completely see.

So, I have not tried to provide a comprehensive treatise on spoon carving but rather to share with you what works for me with an eye towards making useful and practical cooking spoons in sufficient quantity to meet the needs of my crafting.

I find that it is a good means of using up odds and ends of wood from the shop. After more demanding tasks I find it very relaxing to work up a few spoons and allow for my creativity to express itself in this simple way.

Wooden spoons make wonderful gifts. People especially love when the wood is from a tree or a limb that they gave you. With a bandsaw, any limb wood can produce good spoon blanks. It provides them with a connection to the nature that they had known and come to love. The tree may be gone but the memory of it survives in the spoon and that can be passed down from generation to generation.